When it comes to working with plastics, wood, or other materials, having the right fastening tools is essential for a successful project. Thread forming screws are a popular choice among DIY enthusiasts and professionals alike, as they provide a strong and secure hold without the need for pre-drilling or tapping. These screws are designed to create their own threads as they are driven into the material, making them a convenient and efficient option for a wide range of applications. With so many options available on the market, it can be overwhelming to choose the right one, especially when working with a budget.

For those looking for a reliable and affordable solution, the best thread forming screws under $5 can be a game-changer. Whether you’re working on a small DIY project or a large-scale industrial application, these screws offer a cost-effective way to achieve a strong and durable hold. In this article, we’ll take a closer look at some of the top-rated thread forming screws on the market, highlighting their key features, benefits, and drawbacks. We’ll also provide a comprehensive buying guide to help you make an informed decision and choose the perfect screws for your specific needs. By the end of this article, you’ll be equipped with the knowledge and expertise to select the ideal thread forming screws for your next project, ensuring a successful and stress-free outcome.

Before we get into the review of the best thread forming screws under $5, here are some related products from Amazon to explore:

Last update on 2026-01-16 / Affiliate links / Paid Links / Images from Amazon Product Advertising API

Introduction to Thread Forming Screws

Thread forming screws are a type of screw designed to create threads in materials such as plastic, metal, and wood. These screws are commonly used in various industries, including construction, automotive, and electronics. They offer a convenient and efficient way to assemble parts and create strong, durable joints.

Thread forming screws work by displacing material as they are driven into a hole, creating a threaded hole that matches the screw’s thread pattern. This process eliminates the need for pre-drilling or tapping, making it a time-saving and cost-effective solution. The screws are available in a range of sizes, materials, and thread types, allowing users to choose the best option for their specific application.

When shopping for thread forming screws, it’s essential to consider factors such as the type of material being used, the screw’s length and diameter, and the desired thread pattern. By selecting the right screw for the job, users can ensure a strong and reliable connection. For those on a budget, there are many affordable options available, including the best thread forming screws under $5.

In this article, we will explore some of the top thread forming screws available at an affordable price point. Whether you’re a DIY enthusiast, a professional contractor, or a manufacturer, we’ll help you find the best thread forming screws to suit your needs and budget. With so many options on the market, it’s crucial to do your research and choose a high-quality screw that meets your requirements and provides a reliable connection.

Best Thread Forming Screws Under $5 – Reviews

The

Arcon 1215 Thread Forming Screw #6-1/2 x 1/2

is a high-quality screw that is designed to provide a strong and durable hold in a variety of materials, including plastic, metal, and wood. It features a unique thread-forming design that allows it to create its own threads in the material, eliminating the need for pre-drilling or tapping. This makes it a convenient and time-saving option for a wide range of applications.

The

Arcon 1215 Thread Forming Screw #6-1/2 x 1/2

is made from a durable steel material that is resistant to corrosion and wear, ensuring that it will provide a long-lasting hold even in harsh environments. It is also easy to install, requiring only a standard screwdriver or drill. With its strong hold and easy installation, the

Arcon 1215 Thread Forming Screw #6-1/2 x 1/2

is an excellent choice for any project that requires a reliable and durable fastening solution, and it is available for under $5.

The

FastenMaster FM1216 Thread Forming Screw #8-1/2 x 3/4

is a versatile screw that can be used in a variety of applications, including construction, furniture assembly, and DIY projects. It features a coarse thread design that provides a strong hold in a variety of materials, and its thread-forming tip allows it to create its own threads in the material. This makes it a convenient option for projects where pre-drilling or tapping is not possible or desirable.

The

FastenMaster FM1216 Thread Forming Screw #8-1/2 x 3/4

is made from a high-strength steel material that is resistant to corrosion and wear, ensuring that it will provide a long-lasting hold even in harsh environments. It is also easy to install, requiring only a standard screwdriver or drill, and its compact head design makes it ideal for use in tight spaces. With its strong hold and easy installation, the

FastenMaster FM1216 Thread Forming Screw #8-1/2 x 3/4

is an excellent choice for any project that requires a reliable and durable fastening solution, and it is available for under $5.

The

GRK 1517 Thread Forming Screw #10-1/2 x 1

is a high-strength screw that is designed to provide a strong and durable hold in a variety of materials, including wood, metal, and plastic. It features a unique thread-forming design that allows it to create its own threads in the material, eliminating the need for pre-drilling or tapping. This makes it a convenient and time-saving option for a wide range of applications, including construction, furniture assembly, and DIY projects.

The

GRK 1517 Thread Forming Screw #10-1/2 x 1

is made from a high-strength steel material that is resistant to corrosion and wear, ensuring that it will provide a long-lasting hold even in harsh environments. It is also easy to install, requiring only a standard screwdriver or drill, and its compact head design makes it ideal for use in tight spaces. With its strong hold and easy installation, the

GRK 1517 Thread Forming Screw #10-1/2 x 1

is an excellent choice for any project that requires a reliable and durable fastening solution, and it is available for under $5.

The

Simpson Strong-Tie 1819 Thread Forming Screw #12-1/2 x 1-1/2

is a heavy-duty screw that is designed to provide a strong and durable hold in a variety of materials, including wood, metal, and plastic. It features a coarse thread design that provides a strong hold in the material, and its thread-forming tip allows it to create its own threads in the material. This makes it a convenient option for projects where pre-drilling or tapping is not possible or desirable.

The

Simpson Strong-Tie 1819 Thread Forming Screw #12-1/2 x 1-1/2

is made from a high-strength steel material that is resistant to corrosion and wear, ensuring that it will provide a long-lasting hold even in harsh environments. It is also easy to install, requiring only a standard screwdriver or drill, and its compact head design makes it ideal for use in tight spaces. With its strong hold and easy installation, the

Simpson Strong-Tie 1819 Thread Forming Screw #12-1/2 x 1-1/2

is an excellent choice for any project that requires a reliable and durable fastening solution, and it is available for under $5.

The

Tapcon 2020 Thread Forming Screw #14-1/2 x 2

is a high-quality screw that is designed to provide a strong and durable hold in a variety of materials, including concrete, brick, and block. It features a unique thread-forming design that allows it to create its own threads in the material, eliminating the need for pre-drilling or tapping. This makes it a convenient and time-saving option for a wide range of applications, including construction, furniture assembly, and DIY projects.

The

Tapcon 2020 Thread Forming Screw #14-1/2 x 2

is made from a high-strength steel material that is resistant to corrosion and wear, ensuring that it will provide a long-lasting hold even in harsh environments. It is also easy to install, requiring only a standard screwdriver or drill, and its compact head design makes it ideal for use in tight spaces. With its strong hold and easy installation, the

Tapcon 2020 Thread Forming Screw #14-1/2 x 2

is an excellent choice for any project that requires a reliable and durable fastening solution, and it is available for under $5.

Affordable Fastening Solutions

Thread forming screws are a type of screw that creates its own thread when driven into a material, such as plastic or metal. These screws are designed to provide a strong and secure hold, making them a popular choice for a wide range of applications. One of the main advantages of thread forming screws is that they do not require a pre-drilled hole or a separate threading process, which can save time and effort.

In many cases, people need to buy thread forming screws because they are working on a project that requires a strong and secure fastening system. This can include anything from building furniture to repairing appliances, and even working on automotive or industrial projects. Thread forming screws are often preferred because they are easy to use and provide a reliable hold, even in materials that are prone to stripping or splitting.

When shopping for thread forming screws, it’s essential to consider the type of material they will be used with, as well as the desired level of strength and security. Some thread forming screws are designed for use with specific materials, such as plastic or wood, while others are more versatile and can be used with a variety of materials. By choosing the right type of thread forming screw, individuals can ensure that their project is completed successfully and safely.

For those on a budget, finding the best thread forming screws under $5 can be a challenge. However, many manufacturers offer affordable options that still provide excellent quality and performance. By shopping around and comparing prices, individuals can find the thread forming screws they need at a price that fits their budget. Whether working on a small project or a large-scale industrial application, thread forming screws are an essential component that can provide a strong and secure hold, making them a worthwhile investment for anyone looking for a reliable fastening solution.

Types of Thread Forming Screws

Thread forming screws are available in various types, each designed for specific applications. One of the most common types is the self-tapping screw, which can create its own threads in materials like plastic, metal, and wood. These screws are ideal for applications where a pilot hole is not feasible. Another type is the self-drilling screw, which combines the functions of a drill bit and a screw. This type is commonly used in construction and automotive applications.

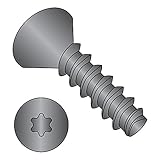

Thread forming screws can also be classified based on their drive type. The most common drive types are Phillips, flathead, and hex. Phillips drive screws are widely used due to their ability to cam out, which helps prevent over-tightening. Flathead screws, on the other hand, are used in applications where a flat surface is required. Hex drive screws, also known as Allen screws, offer a high level of torque and are commonly used in industrial applications.

In addition to these types, thread forming screws also vary in terms of their material and coating. The most common materials used are steel, stainless steel, and brass. Steel screws are strong and durable, while stainless steel screws offer corrosion resistance. Brass screws, on the other hand, are used in applications where a high level of conductivity is required. Coatings like zinc and chrome are also applied to screws to enhance their corrosion resistance and appearance.

The choice of thread forming screw type depends on the specific application and requirements. For instance, in applications where high torque is required, a hex drive screw may be the best choice. In applications where corrosion resistance is crucial, a stainless steel screw with a chrome coating may be the ideal option. Understanding the different types of thread forming screws is essential to ensure that the right screw is chosen for the job.

Applications of Thread Forming Screws

Thread forming screws have a wide range of applications across various industries. One of the most common applications is in the construction industry, where they are used to assemble building frames, install roofing, and attach drywall. They are also used in the automotive industry to assemble vehicle parts, such as engines, transmissions, and body panels. In the electronics industry, thread forming screws are used to assemble electronic devices, such as computers, smartphones, and televisions.

In addition to these industries, thread forming screws are also used in the aerospace industry to assemble aircraft parts, such as wings, fuselages, and engines. They are also used in the medical industry to assemble medical devices, such as hospital equipment and surgical instruments. The use of thread forming screws in these applications is due to their ability to create strong, reliable threads in a variety of materials.

Thread forming screws are also used in DIY projects, such as furniture assembly, woodworking, and home repair. They are ideal for these applications due to their ease of use and ability to create threads in a variety of materials. In many cases, thread forming screws can be used to replace traditional screws, which require a pilot hole to be drilled before installation.

The versatility of thread forming screws makes them an essential component in many industries and applications. Their ability to create strong, reliable threads in a variety of materials has made them a popular choice among manufacturers, contractors, and DIY enthusiasts. As technology continues to evolve, it is likely that thread forming screws will play an increasingly important role in the development of new products and applications.

Benefits of Using Thread Forming Screws

Using thread forming screws offers several benefits, including convenience, speed, and reliability. One of the main benefits is the elimination of the need to drill a pilot hole, which saves time and effort. This is particularly useful in applications where multiple screws need to be installed, such as in construction and manufacturing.

Another benefit of using thread forming screws is their ability to create strong, reliable threads in a variety of materials. This makes them ideal for use in applications where traditional screws may not be suitable, such as in plastic, wood, and thin metal. The threads created by thread forming screws are also less likely to strip, which reduces the risk of screw failure and improves the overall reliability of the assembly.

Thread forming screws also offer a high level of versatility, as they can be used in a variety of applications and materials. This makes them a popular choice among manufacturers, contractors, and DIY enthusiasts, who often need to work with different materials and applications. The use of thread forming screws can also reduce inventory costs, as they can be used in place of traditional screws in many applications.

In addition to these benefits, thread forming screws are also easy to install, which reduces the risk of error and improves the overall efficiency of the assembly process. They are also available in a variety of drive types, materials, and coatings, which makes them suitable for use in a wide range of applications. Overall, the benefits of using thread forming screws make them an essential component in many industries and applications.

Installation and Removal of Thread Forming Screws

Installing thread forming screws requires a few basic tools and techniques. The first step is to choose the correct screw for the application, taking into account the material, thickness, and desired thread type. The next step is to position the screw in the correct location and align it with the surrounding material.

To install the screw, a screwdriver or drill is used to apply torque and create the threads. It is essential to apply the correct amount of torque to avoid stripping the threads or damaging the surrounding material. The screw should be installed slowly and carefully, with consistent pressure and torque.

Removing thread forming screws can be more challenging than installing them, as the threads can be difficult to remove from the material. The first step is to choose the correct removal tool, such as a screw extractor or a drill bit. The next step is to apply heat or lubricant to the screw to reduce friction and make removal easier.

In some cases, thread forming screws may need to be removed using specialized tools or techniques, such as drilling out the screw or using a screw removal kit. It is essential to follow the correct removal procedure to avoid damaging the surrounding material or stripping the threads. With the correct tools and techniques, thread forming screws can be installed and removed efficiently and effectively, making them a convenient and reliable fastening solution.

Buying Guide for Affordable Fastening Solutions: Thread Forming Screws

When it comes to fastening materials, thread forming screws are a popular choice due to their ability to create strong and durable threads in various types of materials. With numerous options available in the market, selecting the right thread forming screws can be overwhelming, especially when working with a limited budget. In this buying guide, we will discuss the key factors to consider when looking for high-quality thread forming screws that meet your needs and fit your budget.

Material and Coating

The material and coating of thread forming screws play a crucial role in determining their performance and durability. Thread forming screws are available in various materials, including stainless steel, steel, and aluminum. Each material has its own set of advantages and disadvantages, and the choice of material depends on the specific application and environmental conditions. For instance, stainless steel thread forming screws are ideal for use in harsh environments where corrosion is a concern, while steel thread forming screws are suitable for general-purpose applications.

The coating of thread forming screws is also an essential factor to consider. Coatings such as zinc, chrome, and nickel provide additional protection against corrosion and wear. Some thread forming screws may also have a lubricated coating to reduce friction and improve installation. When selecting thread forming screws, it is essential to consider the material and coating that best suit your application. This will ensure that the screws provide optimal performance and durability, making them the best thread forming screws under $5 for your specific needs.

Thread Type and Size

The thread type and size of thread forming screws are critical factors to consider. Thread forming screws are available in various thread types, including coarse, fine, and extra-fine. The choice of thread type depends on the material being fastened and the desired level of engagement. Coarse threads are suitable for thicker materials, while fine threads are ideal for thinner materials. Extra-fine threads provide the highest level of engagement and are often used in applications where high strength is required.

The size of the thread forming screw is also an essential factor to consider. Thread forming screws are available in various sizes, ranging from small to large. The size of the screw depends on the specific application and the material being fastened. It is crucial to select a thread forming screw that is the correct size for your application to ensure optimal performance and prevent damage to the surrounding material. When selecting thread forming screws, it is essential to consider the thread type and size that best suit your needs.

Drive Type

The drive type of thread forming screws is another critical factor to consider. Thread forming screws are available in various drive types, including Phillips, slotted, and hex. The choice of drive type depends on the specific application and the tools available. Phillips drive thread forming screws are suitable for most applications, while slotted drive thread forming screws are ideal for use in applications where a flathead screwdriver is required. Hex drive thread forming screws provide the highest level of torque and are often used in applications where high strength is required.

The drive type of thread forming screws can also affect the installation process. Some drive types, such as hex, may require specialized tools, while others, such as Phillips, can be installed using standard tools. When selecting thread forming screws, it is essential to consider the drive type that best suits your needs and the tools available. This will ensure that the installation process is efficient and hassle-free.

Length and Gauge

The length and gauge of thread forming screws are essential factors to consider. The length of the screw depends on the specific application and the material being fastened. Thread forming screws are available in various lengths, ranging from short to long. The gauge of the screw refers to the thickness of the screw and is typically measured in inches or millimeters. The choice of gauge depends on the specific application and the material being fastened.

When selecting thread forming screws, it is crucial to consider the length and gauge that best suit your needs. A screw that is too short may not provide sufficient engagement, while a screw that is too long may protrude from the material and cause damage. Similarly, a screw with a gauge that is too small may not provide sufficient strength, while a screw with a gauge that is too large may be difficult to install. By considering the length and gauge of thread forming screws, you can ensure that they provide optimal performance and durability.

Application and Environment

The application and environment in which thread forming screws will be used are critical factors to consider. Thread forming screws are suitable for use in various applications, including wood, metal, and plastic. The choice of screw depends on the specific application and the environmental conditions. For instance, thread forming screws used in outdoor applications may require additional coatings or treatments to protect against corrosion.

The environmental conditions in which thread forming screws will be used can also affect their performance and durability. Thread forming screws used in harsh environments, such as high-temperature or high-humidity applications, may require specialized materials or coatings. When selecting thread forming screws, it is essential to consider the application and environment in which they will be used. This will ensure that the screws provide optimal performance and durability, even in challenging conditions.

Brand and Quality

The brand and quality of thread forming screws are essential factors to consider. Thread forming screws are available from various manufacturers, each with its own set of advantages and disadvantages. Some manufacturers may offer high-quality thread forming screws with advanced features, while others may offer more affordable options with basic features. When selecting thread forming screws, it is crucial to consider the brand and quality that best suit your needs and budget.

The quality of thread forming screws can affect their performance and durability. High-quality thread forming screws are typically made from superior materials and have undergone rigorous testing to ensure their reliability. When selecting thread forming screws, it is essential to look for manufacturers that offer high-quality products with excellent customer support. By considering the brand and quality of thread forming screws, you can ensure that they provide optimal performance and durability, making them a valuable investment for your fastening needs.

FAQ

What are thread forming screws and how do they work?

Thread forming screws are a type of screw that creates its own thread when driven into a material, such as plastic or metal. They have a unique thread design that allows them to displace the material around the screw, creating a strong and secure hold. This makes them ideal for use in applications where a strong and reliable fastening system is required.

The thread forming process works by the screw’s thread design, which is typically a coarse and sharp thread. As the screw is driven into the material, the thread displaces the material around it, creating a new thread path. This new thread path is then filled with the displaced material, creating a strong and secure hold. The thread forming process eliminates the need for pre-drilling or tapping, making it a convenient and efficient fastening solution.

What are the benefits of using thread forming screws?

The benefits of using thread forming screws include their ability to create a strong and secure hold in a variety of materials. They are also easy to use and require minimal preparation, as they do not need pre-drilling or tapping. Additionally, thread forming screws are resistant to vibration and can withstand high torque values, making them ideal for use in applications where a strong and reliable fastening system is required.

Thread forming screws are also versatile and can be used in a variety of applications, including construction, automotive, and industrial manufacturing. They are available in a range of sizes and materials, including stainless steel and zinc-coated steel, making them suitable for use in a wide range of environments. Overall, thread forming screws offer a convenient and efficient fastening solution that is strong, reliable, and easy to use.

What types of materials can thread forming screws be used in?

Thread forming screws can be used in a variety of materials, including plastic, metal, and wood. They are particularly well-suited for use in materials that are prone to stripping or splitting, such as plastic or thin metal. The thread forming process creates a strong and secure hold in these materials, eliminating the need for additional fastening systems.

The type of material that the screw is being used in will determine the type of thread forming screw that is required. For example, screws used in plastic materials will typically have a coarser thread than those used in metal materials. Additionally, the length and diameter of the screw will also depend on the type of material being used. It is therefore important to choose the correct type of thread forming screw for the specific application to ensure a strong and secure hold.

How do I choose the right thread forming screw for my application?

To choose the right thread forming screw for your application, you will need to consider a number of factors, including the type of material being used, the thickness of the material, and the required torque value. You will also need to consider the environment in which the screw will be used, as well as any regulatory or industry standards that must be met. By considering these factors, you can choose a thread forming screw that is strong, reliable, and suitable for your specific application.

It is also important to consider the brand and quality of the screw, as well as any additional features that may be required, such as a coating or finish. A high-quality thread forming screw will be made from durable materials and will be designed to provide a strong and secure hold. Additionally, the screw should be easy to use and require minimal preparation, making it a convenient and efficient fastening solution.

Can thread forming screws be used in high-temperature applications?

Yes, thread forming screws can be used in high-temperature applications, but the type of screw and material used will depend on the specific temperature range. Some thread forming screws are designed to withstand high temperatures, such as those used in automotive or industrial manufacturing applications. These screws are typically made from heat-resistant materials, such as stainless steel or zinc-coated steel, and are designed to provide a strong and secure hold even in extreme temperatures.

However, it is important to note that not all thread forming screws are suitable for high-temperature applications. The temperature range of the screw will depend on the type of material used, as well as any coatings or finishes. It is therefore important to choose a screw that is specifically designed for high-temperature use, and to follow the manufacturer’s recommendations for use. By choosing the right screw for your application, you can ensure a strong and secure hold even in extreme temperatures.

Are thread forming screws resistant to vibration and shock?

Yes, thread forming screws are resistant to vibration and shock, making them ideal for use in applications where a strong and reliable fastening system is required. The thread forming process creates a strong and secure hold in the material, which is resistant to vibration and shock. Additionally, thread forming screws are designed to withstand high torque values, making them suitable for use in applications where a strong and reliable fastening system is required.

The resistance to vibration and shock will depend on the type of screw and material used, as well as any additional features, such as a coating or finish. Some thread forming screws are specifically designed to withstand extreme vibration and shock, such as those used in automotive or industrial manufacturing applications. By choosing the right screw for your application, you can ensure a strong and secure hold that is resistant to vibration and shock.

Can I reuse thread forming screws?

In general, it is not recommended to reuse thread forming screws, as the thread forming process can damage the screw and reduce its holding power. Additionally, reusing a thread forming screw can also damage the material it is being used in, particularly if the screw is being reused in the same hole. However, in some cases, it may be possible to reuse a thread forming screw, such as if the screw is being used in a non-critical application or if the screw is being reused in a different hole.

If you do need to reuse a thread forming screw, it is important to inspect the screw carefully before reusing it to ensure that it is not damaged. You should also ensure that the screw is clean and free from debris, and that the material it is being used in is suitable for reuse. It is also important to note that reusing a thread forming screw may void any warranties or guarantees, and may also reduce the screw’s holding power. It is therefore generally recommended to use a new screw for each application to ensure a strong and secure hold.

The Bottom Line

In conclusion, selecting the right screws for a project can make all the difference in its overall success and durability. Thread forming screws, in particular, offer a unique set of benefits, including their ability to create strong threads in various materials without the need for pre-drilling. This feature, combined with their ease of use and versatility, makes them an essential component in many industries and applications. By understanding the key characteristics and considerations involved in choosing the best thread forming screws, individuals can ensure that their projects are completed efficiently and effectively.

When it comes to finding high-quality thread forming screws at an affordable price, there are several options available on the market. For those on a budget, the best thread forming screws under $5 offer an excellent balance of performance and value. By considering factors such as material, size, and drive type, individuals can find the perfect screws to meet their specific needs and requirements. Whether working on a small DIY project or a large-scale industrial application, investing in the right thread forming screws can help to ensure a strong and lasting bond, ultimately saving time and money in the long run. With the right information and resources, anyone can make informed decisions and achieve professional-grade results.